Phased Array

Our phased array (PA) instruments produce accurate, detailed cross-sectional pictures of internal structures at fast inspection speeds. Phased array technology uses multiple ultrasonic elements and electronic time delays to create beams that can be steered, scanned, swept, and focused electronically for fast inspection, full data storage, and multiple angle inspections. Phased array technology provides precise measurement with the most reliable results.

OmniScan X3

OmniScan X3

The OmniScan™ X3 flaw detector is a complete phased array toolbox. Innovative TFM delivers outstanding images that help inspectors identify flaws with confidence while powerful software features and simple workflows help you get to work fast.

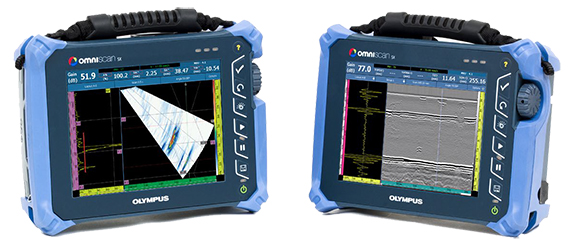

OmniScan SX

OmniScan SX

The single group, lightweight OmniScan SX flaw detector features an easy-to-read 8.4-inch (21.3 cm) touch screen and provides cost-effective solutions. The OmniScan SX comes in two models: the SX PA and SX UT. The SX PA is a 16:64PR unit, which, like the UT-only SX UT, is equipped with a conventional UT channel for P/E, P-C, or TOFD inspections.

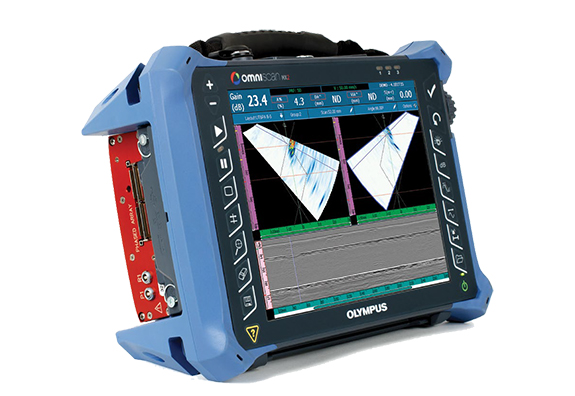

OmniScan MX2

OmniScan MX2

The OmniScan MX2 features a new phased array module (PA2) with a UT channel, and a two-channel conventional ultrasound module (UT2) that can be used for TOFD (Time-of-Flight Diffraction), as well as new software programs that expand the capabilities of the successful OmniScan MX2 platform.

EPOCH 1000 Series

EPOCH 1000 Series

The EPOCH 1000 is an advanced conventional ultrasonic flaw detector that can be upgraded with phased array imaging at an authorized Olympus service center. Key features include EN12668-1 compliant, 37 digital receiver filter selections, and a 6 kHz pulse repetition rate for high-speed scanning.

FOCUS PX / PC / SDK

FOCUS PX / PC / SDK

The scalable FOCUS PX acquisition unit and FocusPC software incorporate the latest phased array and conventional UT technologies for easy integration on automated and semi-automated systems. The FOCUS PX and its software’s ability to generate and save C-scan and A-scan raw data make them the perfect choice for applications where the inspection verdict is based on post-inspection data analysis. This includes applications in industries like aerospace (composite laminate), power generation (wind blade), transportation (train wheels), metal (forged parts), and more. Optional FocusControl, FocusData, and OpenView software development kits (SDKs), are compatible with the FOCUS PX unit so that customers can develop their own application software